You can find Scania fault codes in the list below. Fault codes generated in the CAN network are sent via CAN message DM1. This document describes how to interpret these fault codes from the DM1 message.

SPN: Suspect Parameter Number

FMI: Failure Mode Identifiers

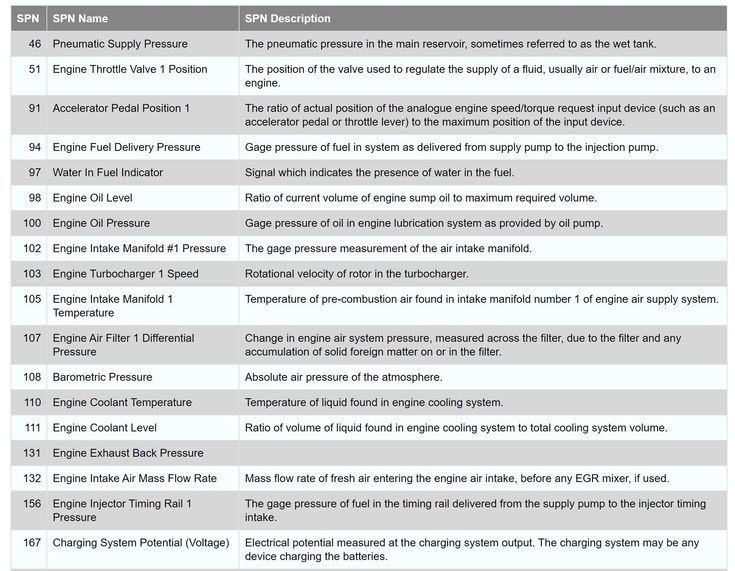

| SPN | SPN Name | SPN Description |

| 46 | Pneumatic Supply Pressure | The pneumatic pressure in the main reservoir, sometimes referred to as the wet tank. |

| 51 | Engine Throttle Valve 1 Position | The position of the valve used to regulate the supply of a fluid, usually air or fuel/air mixture, to an en- gine. |

| 91 | Accelerator Pedal Position 1 | The ratio of actual position of the analogue engine speed/torque request input device (such as an accel- erator pedal or throttle lever) to the maximum position of the input device. |

| 94 | Engine Fuel Delivery Pressure | Gage pressure of fuel in system as delivered from supply pump to the injection pump. |

| 97 | Water In Fuel Indicator | Signal which indicates the presence of water in the fuel. |

| 98 | Engine Oil Level | Ratio of current volume of engine sump oil to maximum required volume. |

| 100 | Engine Oil Pressure | Gage pressure of oil in engine lubrication system as provided by oil pump. |

| 102 | Engine Intake Manifold #1 Pressure | The gage pressure measurement of the air intake manifold. |

| 103 | Engine Turbocharger 1 Speed | Rotational velocity of rotor in the turbocharger. |

| 105 | Engine Intake Manifold 1 Temperature | Temperature of pre-combustion air found in intake manifold number 1 of engine air supply system. |

| 107 | Engine Air Filter 1 Differential Pressure | Change in engine air system pressure, measured across the filter, due to the filter and any accumulation of solid foreign matter on or in the filter. |

| 108 | Barometric Pressure | Absolute air pressure of the atmosphere. |

| 110 | Engine Coolant Temperature | Temperature of liquid found in engine cooling system. |

| 111 | Engine Coolant Level | Ratio of volume of liquid found in engine cooling system to total cooling system volume. |

| 131 | Engine Exhaust Back Pressure | |

| 132 | Engine Intake Air Mass Flow Rate | Mass flow rate of fresh air entering the engine air intake, before any EGR mixer, if used. |

| 156 | Engine Injector Timing Rail 1 Pressure | The gage pressure of fuel in the timing rail delivered from the supply pump to the injector timing intake. |

| 167 | Charging System Potential (Voltage) | Electrical potential measured at the charging system output. The charging system may be any device charging the batteries. |

| 168 | Battery Potential/Power Input 1 | This parameter measures the first source of battery potential as measured at the input of the ECM/actu- ator etc. coming from one or more batteries, irrespective of the distance between the component and the battery. |

| 171 | Ambient Air Temperature | Temperature of air surrounding vehicle. |

| 172 | Engine Air Intake Temperature | Temperature of air entering vehicle air induction system. |

| 174 | Engine Fuel Temperature 1 | Temperature of fuel passing through the first fuel control system. |

| 175 | Engine Oil Temperature 1 | Temperature of the engine lubricant. |

| 188 | Engine Speed At Idle, Point 1 (Engine Configuration) | Stationary low idle speed of engine which includes influences due to engine temperature (after power up) and other stationary changes (calibration offsets, sensor failures, etc). |

| 190 | Engine Speed | Actual engine speed which is calculated over a minimum crankshaft angle of 720 degrees divided by the number of cylinders. |

| 234 | Software Identification | Software identification of an electronic module. |

| 532 | Engine Speed At High Idle, Point 6 (Engine Configuration) Engine speed of high idle of the engine torque map. | |

| 558 | Accelerator Pedal 1 Low Idle Switch | Switch signal which indicates the state of the accelerator pedal 1 low idle switch. |

| 559 | Accelerator Pedal Kickdown Switch | Switch signal which indicates whether the accelerator pedal kickdown switch is opened or closed. |

| 590 | Engine Idle Shutdown Timer State | Status signal which indicates the current mode of operation of the idle shutdown timer system. |

| 597 | Brake Switch | Switch signal which indicates that the driver operated brake foot pedal is being pressed. |

| 598 | Clutch Switch | Switch signal which indicates that the clutch pedal is being pressed. |

| 636 | Engine Position Sensor | |

| 641 | Engine Variable Geometry Turbocharger Actuator #1 | Actuator that controls the variable geometry turbocharger geometry. |

| 645 | Engine Tachometer Signal Output | |

| 651 | Engine Injector Cylinder #01 | |

| 652 | Engine Injector Cylinder #02 | |

| 653 | Engine Injector Cylinder #03 | |

| 654 | Engine Injector Cylinder #04 | |

| 655 | Engine Injector Cylinder #05 | |

| 656 | Engine Injector Cylinder #06 | |

| 657 | Engine Injector Cylinder #07 | |

| 658 | Engine Injector Cylinder #08 | |

| 677 | Engine Starter Motor Relay | Activates the starter. |

| 723 | Engine Speed 2 | The engine speed as measured by speed sensor 2. |

| 968 | Engine Idle Increment Switch | Switch signal which indicates the position of the idle increment switch. |

| 972 | Accelerator Interlock Switch | Switch signal used to disable the accelerator and remote accelerator inputs, causing the engine to return to idle. |

| 974 | Remote Accelerator Pedal Position | The ratio of actual position of the remote analogue engine speed/torque request input device (such as an accelerator pedal or throttle lever) to the maximum position of the input device. |

| 986 | Requested Percent Fan Speed | Fan speed as a ratio of the actual fan drive (current speed) to the fully engaged fan drive (maximum fan speed). |

| 1086 | Parking and/or Trailer Air Pressure | The pneumatic pressure in the circuit or reservoir for the parking brake and/or the trailer supply. |

| 1108 | Engine Protection System Timer Override | Status signal which indicates the status of the override feature of the engine protection system timer. |

| 1110 | Engine Protection System has Shutdown Engine | Status signal which indicates whether or not the engine protection system has shutdown the engine. |

| 1239 | Engine Fuel Leakage 1 | Status signal which indicates fuel leakage in the fuel rail of the engine. Location can be either before or after the fuel pump. |

| 1322 | Engine Misfire for Multiple Cylinders | When a misfire occurs in any one of the cylinders. |

| 1323 | Engine Misfire Cylinder #1 | Engine misfire detected in cylinder. |

| 1324 | Engine Misfire Cylinder #2 | Engine misfire detected in cylinder. |

| 1325 | Engine Misfire Cylinder #3 | Engine misfire detected in cylinder. |

| 1326 | Engine Misfire Cylinder #4 | Engine misfire detected in cylinder. |

| 1327 | Engine Misfire Cylinder #5 | Engine misfire detected in cylinder. |

| 1328 | Engine Misfire Cylinder #6 | Engine misfire detected in cylinder. |

| 1329 | Engine Misfire Cylinder #7 | Engine misfire detected in cylinder. |

| 1330 | Engine Misfire Cylinder #8 | Engine misfire detected in cylinder. |

| 1135 | Engine Oil Temperature 2 | Temperature of the engine lubricant. |

| 1442 | Engine Fuel Valve 1 Position | The position of a gaseous fuel valve that is metering the fuel flow to the engine. |

| 1443 | Engine Fuel Valve 2 Position | The position of a gaseous fuel valve that is metering the fuel flow to the engine. |

| 1483 | Source Address of Controlling Device for Engine Control | The source address of the SAE J1939 device currently controlling the engine. |

| 1484 | Other ECUs Have Reported Fault Codes Affecting Opera- tion | |

| 1485 | ECM Main Relay | |

| 1569 | Engine Protection Torque Derate | Torque has been derated for protection of the engine. |

| 1632 | Engine Torque Limit Feature | Torque limit rating described in the current record. |

| 1639 | Fan Speed | The speed of the fan associated with engine coolant system. |

| 1675 | Engine Starter Mode | Start cannot take place for one of several different reasons. |

| 1761 | Aftertreatment 1 Diesel Exhaust Fluid Tank Level | Ratio of volume of diesel exhaust fluid to the total volume of diesel exhaust fluid storage container. |

| 2609 | Cab A/C Refrigerant Compressor Outlet Pressure | Gage pressure at the compressor outlet in the cab air conditioning system. |

| 2791 | Engine Exhaust Gas Recirculation 1 (EGR1) Valve Con- trol | Desired percentage of maximum Exhaust Gas Recirculation (EGR) valve opening. |

| 2797 | Engine Injector Group 1 | A first collection of fuel injector circuits that are grouped together. |

| 2798 | Engine Injector Group 2 | A second collection of fuel injector circuits that are grouped together. |

| 2858 | Machine Data Configuration 1 | There is a problem involving the parameter list for the data structure for configuring operations within the Controller Application being communicated with. |

| 2859 | Machine Data Configuration 2 | There is a problem involving one (or more) of the PGN(s) within the parameter list for the data structure for configuring operations within the Controller Application being communicated with. |

| 2860 | Machine Data Configuration 3 | There is a problem involving the first output control list for the data structure for configuring operations within the Controller Application being communicated with. |

| 2861 | Machine Data Configuration 4 | There is a problem involving the second output control list for the data structure for configuring opera- tions within the Controller Application being communicated with. |

| 2862 | Machine Data Configuration 5 | There is a problem involving the third output control list for the data structure for configuring operations within the Controller Application being communicated with. |

| 3031 | Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature | Temperature of the diesel exhaust fluid in the storage tank. |

| 3216 | Aftertreatment 1 Intake NOx | The amount of combined NO and NO2 in the exhaust entering the aftertreatment system measured by a NOx sensor at the aftertreatment intake, represented in NOx molecule parts per million non-NOx mol- ecules in exhaust bank 1. |

| 3226 | Aftertreatment 1 Outlet NOx | The amount of combined NO and NO2 in the exhaust entering the aftertreatment system measured by a NOx sensor at the aftertreatment outlet, represented in NOx molecule parts per million non-NOx mole- cules in exhaust bank 1. |

| 3241 | Aftertreatment 1 Exhaust Gas Temperature 1 | The reading from the exhaust gas temperature sensor located farthest upstream in the aftertreatment sys- tem in exhaust bank 1. |

| 3242 | Aftertreatment 1 Diesel Particulate Filter Intake Gas Tem- perature | Temperature of engine combustion by-products entering the diesel particulate filter in exhaust bank 1. |

| 3245 | Aftertreatment 1 Exhaust Gas Temperature 3 | The reading from the exhaust gas temperature sensor located farthest downstream in the aftertreatment system in exhaust bank 1. |

| 3246 | Aftertreatment 1 Diesel Particulate Filter Outlet Gas Tem- perature | Temperature of engine combustion by-products leaving the diesel particulate filter exhaust in exhaust bank 1. |

| 3249 | Aftertreatment 1 Exhaust Gas Temperature 2 | The reading from the exhaust gas temperature sensor located midstream of the other two temperature sensors in the aftertreatment system in exhaust bank 1. |

| 3251 | Aftertreatment 1 Diesel Particulate Filter Differential Pres- Exhaust differential pressure measured between the intake and exhaust of a diesel particulate filter in sure exhaust bank 1. | |

| 3275 | Aftertreatment 2 Exhaust Gas Temperature 1 | The reading from the exhaust gas temperature sensor located farthest upstream in the aftertreatment sys- tem in exhaust bank 2. |

| 3279 | Aftertreatment 2 Exhaust Gas Temperature 3 | The reading from the exhaust gas temperature sensor located farthest downstream in the aftertreatment system in exhaust bank 2. |

| 3283 | Aftertreatment 2 Exhaust Gas Temperature 2 | The reading from the exhaust gas temperature sensor located midstream of the other two temperature sensors in the aftertreatment system in exhaust bank 2. |

| 3340 | Engine Charge Air Cooler 1 Intake Pressure | Pressure of air at intake to 1st or only charge air cooler, from multiple first stage turbochargers being cooled and feeding multiple second stage turbochargers. |

| 3360 | Aftertreatment 1 Diesel Exhaust Fluid Controller | The Diesel Exhaust Fluid Controller has the ability to read attributes of the SCR system, including but not limited to, diesel exhaust fluid level, diesel exhaust fluid temperature, diesel exhaust fluid quality, and diesel exhaust fluid dosing rate. |

| 3361 | Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit | The diesel exhaust fluid dosing unit is a device that mixes the diesel exhaust fluid and air, and delivers a metered quantity of this mixture to the exhaust stream. |

| 3362 | Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit Input Lines | The diesel exhaust fluid dosing unit is a device that mixes the diesel exhaust fluid and air, such that it contains an input line from the air tank and an input line from the diesel exhaust fluid tank. |

| 3363 | Aftertreatment 1 Diesel Exhaust Fluid Tank Heater | Percentage of heating applied to the aftertreatment 1 diesel exhaust fluid tank heater. |

| 3464 | Engine Throttle Actuator 1 Control Command | The control command to throttle actuator 1, normalized to percent. |

| 3471 | Aftertreatment 1 Fuel Pressure Control Actuator | Diagnostic SPN for the actuator controlling aftertreatment 1 fuel pressure. |

| 3472 | Aftertreatment 1 Air Pressure Control Actuator | Diagnostic SPN for the actuator controlling aftertreatment 1 air pressure. |

| 3480 | Aftertreatment 1 Fuel Pressure 1 | First fuel pressure measurement for the aftertreatment 1 system. |

| 3485 | Aftertreatment 1 Supply Air Pressure | Pressure of the supply air for aftertreatment 1. |

| 3515 | Aftertreatment 1 Diesel Exhaust Fluid Temperature 2 | Temperature of the diesel exhaust fluid at the device measuring diesel exhaust fluid quality. |

| 3516 | Aftertreatment 1 Diesel Exhaust Fluid Concentration | A measure of the concentration of urea in water. |

| 3563 | Engine Intake Manifold #1 Absolute Pressure | The absolute pressure measurement of the air intake manifold. |

| 3607 | Engine Emergency (Immediate) Shutdown Indication | A signal issued by the engine control system to a user or external system indicating that it is immediately shutting the engine down. |

| 3673 | Engine Throttle Valve 2 Position | The sensed position feedback of the valve, coming from a second electrical actuator for a second throttle plate, used to regulate the supply of a fluid, usually air or fuel//air mixture. |

| 3822 | Engine Exhaust Gas Recirculation 1 Valve 2 Position | The position of the second exhaust gas recirculation valve expressed as a percentage of full travel. |

| 3936 | Aftertreatment Diesel Particulate Filter System | Non-specific failures of the aftertreatment diesel particulate filter system. |

| 4090 | NOx limits exceeded, root cause unknown | On-Board Diagnostics has determined that the limits for NOx in the exhaust stream have been exceeded, but the root cause cannot be determined by the OBD system. |

| 4094 | NOx limits exceeded due to Insufficient Diesel Exhaust Fluid Quality | On-Board Diagnostics has determined that the limits for NOx in the exhaust stream have been exceeded due to an insufficient diesel exhaust fluid quality. |

| 4095 | NOx limits exceeded due to Interrupted Diesel Exhaust Fluid Dosing | On-Board Diagnostics has determined that the limits for NOx in the exhaust stream have been exceeded due to an interruption in diesel exhaust fluid dosing activity. |

| 4096 | NOx limits exceeded due to Empty Diesel Exhaust Fluid Tank | On-Board Diagnostics has determined that the limits for NOx in the exhaust stream have been exceeded due to the diesel exhaust fluid tank being empty. |

| 4201 | Engine Speed 1 | The engine speed as measured by speed sensor 1. |

| 4202 | Engine Speed 3 | The engine speed as measured by speed sensor 3. |

| 4225 | NOx limits exceeded due to error in the NOx control sys- tem | On-Board Diagnostics has determined that the limits for NOx in the exhaust stream have been exceeded due to an error in the NOx control system. |

| 4301 | Aftertreatment 1 Fuel Injector 1 Heater Control | Heating level that the controller is commanding the aftertreatment 1 fuel injector 1 heater control to maintain. |

| 4334 | Aftertreatment 1 Diesel Exhaust Fluid Doser Absolute Pressure | The SCR dosing diesel exhaust fluid absolute pressure (measured closest to dosing valve) for aftertreat- ment system 1 (exhaust bank 1). |

| 4337 | Aftertreatment 1 Diesel Exhaust Fluid Dosing Temperature The diesel exhaust fluid dosing temperature (measured closest to dosing valve) for aftertreatment system 1 (exhaust bank 1). | |

| 4341 | Aftertreatment 1 Diesel Exhaust Fluid Line Heater 1 Pre- liminary FMI | Used to identify the applicable J1939-73 FMI detected in the diesel exhaust fluid line heater 1, by the manufacturer’s control software in exhaust bank 1. |

| 4343 | Aftertreatment 1 Diesel Exhaust Fluid Line Heater 2 Pre- liminary FMI | Used to identify the applicable J1939-73 FMI detected in the diesel exhaust fluid line heater 2, by the manufacturer’s control software in exhaust bank 1. |

| 4345 | Aftertreatment 1 Diesel Exhaust Fluid Line Heater 3 Pre- liminary FMI | Used to identify the applicable J1939-73 FMI detected in the diesel exhaust fluid line heater 3, by the manufacturer’s control software in exhaust bank 1. |

| 4347 | Aftertreatment 1 Diesel Exhaust Fluid Line Heater 4 Pre- liminary FMI | Used to identify the applicable J1939-73 FMI detected in the diesel exhaust fluid line heater 4, by the manufacturer’s control software in exhaust bank 1. |

| 4374 | Aftertreatment 1 Diesel Exhaust Fluid Pump Motor Speed | Rotational speed of the motor driving a pump for diesel exhaust fluid used in an aftertreatment system. |

| 4427 | Aftertreatment 2 Diesel Exhaust Fluid Tank Temperature | Temperature of the diesel exhaust fluid in the storage tank. |

| 4782 | Diesel Particulate Filter 1 Soot Density | Soot density in diesel particulate filter 1. |

| 4809 | Aftertreatment 1 Warm Up Diesel Oxidation Catalyst In- take Temperature | The temperature measured at the intake of the warm up oxidation catalytic converter in exhaust bank 1. |

| 4810 | Aftertreatment 1 Warm Up Diesel Oxidation Catalyst Out- The temperature measured at the outlet of the warm up oxidation catalytic converter in exhaust bank 1. let Temperature | |

| 4814 | Engine Coolant Pump command | Command for a coolant pump that can be driven at varying output level. |

| 5264 | Engine Exhaust Gas Recirculation 2 (EGR2) Valve Con- trol | Desired percentage of maximum Exhaust Gas Recirculation 2 (EGR2) valve opening. 0% means the valve is closed. 100% means maximum opening (full gas flow). |

| 5265 | Engine Exhaust Gas Recirculation 2 (EGR2) Valve 2 Con- trol | Desired percentage of maximum Exhaust Gas Recirculation 2 (EGR2) valve 2 opening. 0% means the valve is closed. 100% means maximum opening (full gas flow). |

| 5285 | Engine Charge Air Cooler 1 Efficiency | An indication of the CAC’s ability to reduce the temperature of the combustion air that is being routed through the CAC1. |

| 5401 | Engine Turbocharger Turbine Bypass Actuator | Diagnostic SPN for the actuator controlling the engine turbocharger turbine bypass valve. |

| 5419 | Engine Throttle Actuator 1 | Device used to control the flow of air or air/fuel mix to the engine. |

| 5421 | Engine Turbocharger Wastegate Actuator 1 | Device used to control the turbocharger wastegate. |

| 5435 | Aftertreatment 1 Diesel Exhaust Fluid Pump State | State of Aftertreatment 1 Diesel Exhaust Fluid dosing pump. |

| 5485 | Aftertreatment 1 Diesel Exhaust Fluid Pump Orifice Flow | The Exhaust Emission Controller aftertreatment reagent pump orifice flow. Could indicate that the flow is being restricted. |

| 5543 | Engine Exhaust Brake Actuator Command | The control command applied to the engine exhaust brake actuator. |

| 5541 | Engine Turbocharger 1 Turbine Outlet Pressure | Gage pressure of the combustion by-products exiting the turbine side of the turbocharger 1. |

| 5706 | Aftertreatment 1 Diesel Exhaust Fluid Pump Heater | Percentage of heating applied to the aftertreatment 1 diesel exhaust fluid pump heater. |

| 5743 | Aftertreatment Selective Catalytic Reduction Temperature Sensor Module | Module will take temperature sensor inputs from the Aftertreatment Selective Catalytic Reduction Tem- perature Sensors and multiplex the sensor values to the engine ECU via the J1939 network. |

| 5745 | Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit Heater | Aftertreatment DEF heater internal to the Aftertreatment Dosing Unit. |

| 5841 | Diesel Exhaust Fluid Quality Malfunction | The diagnostic system has determined that the engine has been operated with a diesel exhaust fluid (re- agent) quality malfunction. |