Engine diagnostics

Engine diagnostics can be performed by scanning the scan-200 or by checking the fault codes displayed on the instrument panel with a flashing indicator light.

of the engine.

We recommend that you use a diagnostic scanner as it provides a quick and accurate check.

Diagnostic procedure

a) Turn the main switch to the battery “on” position.

b) Turn the ignition key to the “ON” position.

c) The engine doesn’t work.

d) Press the engine diagnostic button. (Hold for 2 SEC).

e) The indicator light on the instrument panel will start flashing.

f) Check the fault codes and then turn the ignition key to the “OFF” position.

Fault code display

The following examples show how to display the fault codes using the engine light.

a. With the engine diagnostic button on, observe the engine light.

b. The engine light will flash indicating the first digit of the fault code, then pause and flash again indicating the second digit of the fault code. For example, if the fault code is “21”, the engine light will flash twice (first digit “2″), then pause for 1 second, then flash again (second digit “1”). The loop is repeated to make the fault code clearer.

c. If you wish to display two or more fault codes, the first code will be displayed 3 times, the next code will be displayed after a 3 second pause. As indicated above, each fault code is repeated 3 times.

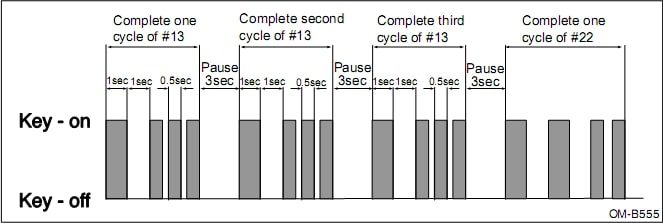

d. The following is an example of the display of fault codes when faults № 13 and № 22 are detected simultaneously.

The engine is switched off and the ignition key is in the ON position.

The light flashes once, then flashes 3 times after 1 second and the whole sequence is repeated 3 times: fault code display 13 completed.

The light flashes twice, then flashes twice after 1 second. The whole sequence is repeated 3 times: Fault code display 22 is closed.

At the end of a cycle there should be a pause of 3 seconds.

The fault code is repeated until the procedure is completed.

Clearing the fault code

The faults stored in the memory of the electronic control module (ECM) can be easily removed using the scanner.

The history of cleared fault codes is automatically removed from the ECU memory after 5 days.

The cleared fault codes can be manually cleared from the ECU memory by turning the ignition on and off 5 times. Do not use this method permanently as it will affect the search time of the service centre using the scanner. It is necessary to reproduce the fault conditions in real conditions Engine operation when the car is moving.

Table of fault codes for Daewoo Novus Ultra

| Fault Code | Fault content | Status | Conditions of Occurrence |

| 1.1 | No signal from temperature sensorCoolant | С | Faulty sensor/wiringCoolant temperature too high |

| 1.2 | No signal from fuel temperature sensor | С | Faulty sensor/wiring the fuel temperature is too high |

| 1.3 | No signal from temperature sensorCharge Air | С | Inlet air temperature IntercoolerAbnormallyHigh. Defective engine/turbocharger/ Intercooler |

| 1.4 | No signal from pressure sensor Charge Air | С | Faulty sensor/wiringInlet pressure, after Intercooler, abnormally high defective engine/turbocharger/ Intercooler |

| 1.6 | No signal from atmospheric air pressure sensor | С | Atmospheric pressure sensor attached to the ECU is defective |

| 1.7 | No signal from oil temperature sensor | N | Faulty sensor/wiring the oil temperature is too high |

| 1.8 | No signal from oil pressure sensor | С | Faulty sensor/wiringOil pressure too low (leakage, etc.) |

| 2.1 | Incorrect battery voltageBattery | С | Battery/generator/ECU Faulty |

| 2.2 | No signal from fuel pressure sensor | В | Faulty sensor/wiring |

| 2.3 | No signal from the electronic accelerator pedal | В | Faulty sensor/wiring/accelerator pedal switch |

| 2.4 | No signal from the electronic accelerator pedal | В | Foot brake and accelerator pedal are used simultaneously while drivingFaulty sensor/switch/foot brake wiring |

| 2.5 | Faulty car speed sensor and tachometer | С | Faulty sensor/car tachometer/wiring |

| Fault code | Fault content | Status | Conditions of Occurrence |

| 2.7 | No signal from the clutch pedal sensor | С | Faulty sensor/wiring clutch pedal |

| 2.8 | No signal from the brake pedal sensor | С | Faulty sensor/wiring harness brake pedal |

| 2.9 | No signal from Cruise control switch | С | Faulty switch/wiring harness |

| 3.2 | The pressure in the fuel ramp is abnormallyLarge deviations | В | The pressure in the fuel ramp outside the permissible |

| 3.6 | Incorrect input signal value whenOperating system ASR | N | ASR plug/wiring Harness Faulty |

| 3.7 | Non-standard signal on CAN bus system ASR and automatic transmission | N | ASR plug/wiring harness and automatic transmission faulty |

| 3.8 | Warning that the speed of rotationEngine is excessively high | С | Exceeding the maximum permissible engine speed(Engine operation in different) |

| 3.9 | Internal ECU relay malfunction (ECU block protection) | В | Operation of the ECU protection due to the short circuit in the wiring/sensors. As a rule, there is also another fault code (pedal sensors and Etc)The internal protective relay ECU is malfunctioning. Failure to supply electricity |

| 4.1 | Emergency stopEngine | В | Motor Emergency Stop |

| 4.2 | No signal from crankshaft speed sensor | С | SENSOR/socket/wiring harness faulty sensor gap |

| 4.3 | No signal from camshaft speed sensor | С | Sensor/connector/harness wiring FaultyIncorrect sensor clearance |

| 4.4 | Engine speed sensor faulty | С | The discrepancy between the signal values of crankshaft sensors andCamshaft |

| 4.5 | The data storage unit in the ECU memory is faulty | С | The error occurs while storing important technical data in the ECU memory, when the engine is switched off |

| 4.6 | Does not start after the power supply isECU | С | Emergency initialization of ECU unit |

| 4.7 | The pressure limit valve in the fuel ramp opens abnormally highMain pressure | В | The pressure limit valve is opened by force at an abnormally high main pressure greater than the pressure of the high pressure pump |

| 4.8 | Faulty power source | N | Battery voltage incorrect: ECU, battery or generator faulty |

| Fault Code | Fault content | Status | Conditions of Occurrence |

| 4.9 | The voltage on the injector (№ 1, 5, 3) deviates from the required value | В | Cable/Injector connector faulty or defective ECU |

| 5.1 | The voltage on the injector (№ 6, 2, 4) deviates from the required value | В | |

| 5.8 | Contact with № 1 injector connector is broken | В | Cable/Injector Connector Faulty |

| 5.9 | Contact with the № 5 injector connector is broken | В | |

| 6.1 | Contact with the № 3 injector connector is broken | В | |

| 6.2 | Contact with the № 6 injector connector is broken | В | |

| 6.3 | Contact with the № 2 injector connector is broken | В | |

| 6.4 | Contact with the № 4 injector connector is broken | В | |

| 6.6 | contact with the control lamp of the Glow candleFaulty | N | Lamp/connector/wiring Harness Faulty |

| 7.1 | Contact with faulty diagnostic lamp | N | Lamp/connector/wiring Harness Faulty |

| 7.2 | The relay of the candle is malfunctioning | С | Relay/connector/wiring harness malfunction |

| 7.3 | Relay № 2 Auxiliary engine brake is malfunctioning | N | Solenoid/connector/wiring Harness Faulty |

| 7.5 | Relay № 1 Auxiliary engine brakeinvalid | N | Solenoid/connector/wiring Harness Faulty |

| 8.3 | Contact with the fuel pump control valve is broken | С | Fuel pump control valve/wiring harness Faulty |

| 8.6 | Car engine speed meter does not work | N | Tachometer Motor/Harness wiring Faulty |

| 9.1 | Abnormal launch | В | The startup procedure is incorrect. Faulty ECU, power failure |

| Fault Code | Fault content | Status | Conditions of Occurrence |

| 9.2 | Low-quality ignition in the cylinder № 1 | С | Faulty injector, low compression pressure,Faulty camshaft/crankshaft speed sensor signal |

| 9.3 | Low-quality ignition in the cylinder № 5 | С | |

| 9.4 | Low-quality ignition in the cylinder № 3 | С | |

| 9.5 | Low-quality ignition in the cylinder № 6 | С | |

| 9.6 | Low-quality ignition in the cylinder № 2 | С | |

| 9.7 | Low-quality ignition in the cylinder № 4 | С | |

| 9.8 | Low-quality ignition in multiple cylinders | С | |

| 9.9 | Injector Open Too long | С | Injector operation time exceeds standard values |

| 10.1 | Engine speed abnormally high (optional function) | С | The error occurs when calculating the engine speed withUsing the camshaft/crankshaft speed sensor |

| 10.2 | Contact with electronic accelerator pedalWrong | В | The foot brake and the accelerator pedal work simultaneously,When the car starts |

| 10.3 | Malfunctioning Cooling Fan | С | Faulty sensor/connector/wiring Harness |

| 10.4 | Fuel pressure is wrong | В | Large fluctuations of fuel pressure in the fuel ramp |

| 11.1 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.2 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.3 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.4 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.5 | Smooth operation of the engine is not standard | N | Excessive injector solenoid Core deviation |

| 11.6 | Smooth operation of the engineNon | N | Excessive injector solenoid Core deviation |

* Status of malfunction

N: No Disruption of engine performance and performance.

С: Requires Check after work (no need for emergency check).

В: Requires Check and take action after working at low speed during the event.